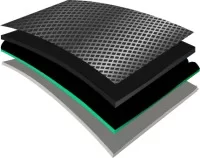

Our cutting-edge blended fabric technology and global infrastructure are uniquely qualified to position you as a leader in your industry. E Squared innovation will bring your company into the future. Our equipment is built to be versatile, including product lines for a variety of industries with strict specifications where products need to remain durable even under the harshest conditions.

Connect with a member of the E Squared team

to analyze your specific goals. We’ll work to provide the solution you’ve been looking for.