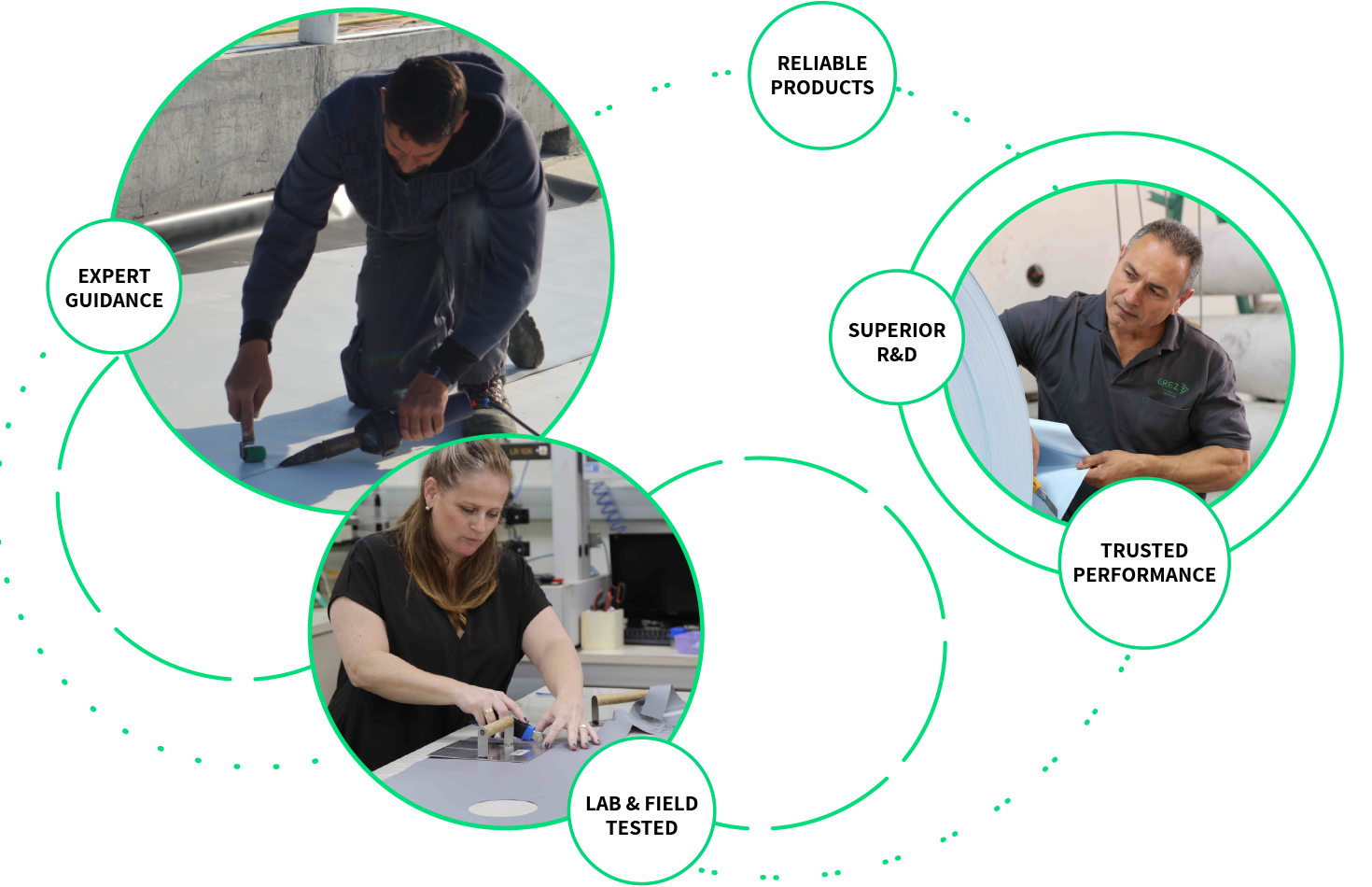

PARTNERING WITH E Squared

We view everyone we work with at E Squared as our partners. From our customers and suppliers to our employees, we are all partners in this endeavor. We know that our direct customers are not the final users of our products, and therefore we strive to work with our customers to understand what their needs and their customers’ needs are. If our customers are not successful in delivering a finished product, we won’t be either. We strive to be transparent and direct and to give prompt answers as to delivery and product inquiries and issues.