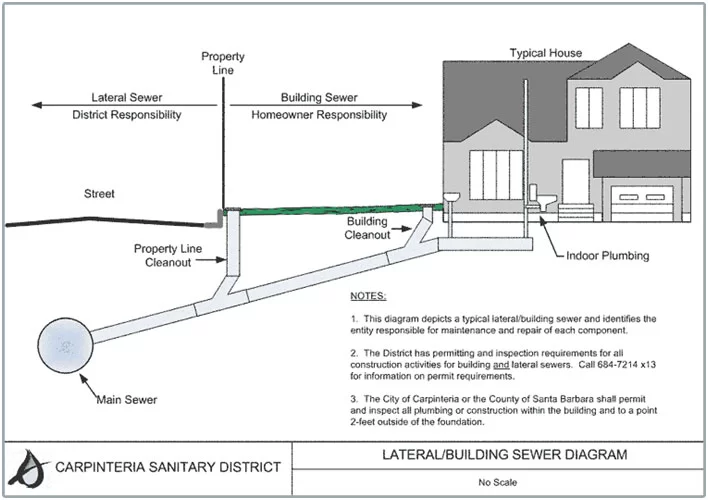

Cured-In-Place Pipe (CIPP) technology has revolutionized the field of sewer and pipeline rehabilitation, offering a cost-effective and minimally disruptive solution to address aging or damaged infrastructure. Within the realm of CIPP, there exists a distinction between mainline and lateral applications, each serving a unique purpose in the rehabilitation of underground pipelines. Main Line is considered as the Sewer Main line connected to treatment facilities, whereas Lateral is the service pipe from the property line to the mainline.

Mainline CIPP and lateral CIPP are two variants of the same technology, yet they are tailored to address different sections of a sewer or pipeline system. Understanding the differences between these applications is crucial for municipalities, engineers, and contractors involved in the maintenance and rehabilitation of underground infrastructure.

Mainline CIPP primarily focuses on rehabilitating larger diameter pipes that form the main network of a sewer system. These are the primary conduits that collect and transport wastewater from various sources to treatment facilities. The mainline CIPP process involves the insertion of a flexible, resin-impregnated liner into the existing pipe. This liner is then inflated, adhering to the inner walls of the host pipe and forming a seamless, durable, and corrosion-resistant new pipe within the old one.

One of the key advantages of mainline CIPP is its ability to rehabilitate long stretches of pipeline with minimal excavation. This is particularly beneficial in densely populated urban areas where traditional open-cut methods would be disruptive and costly. Mainline CIPP also enhances hydraulic efficiency by improving the flow capacity of the rehabilitated pipes and reducing the risk of leaks.

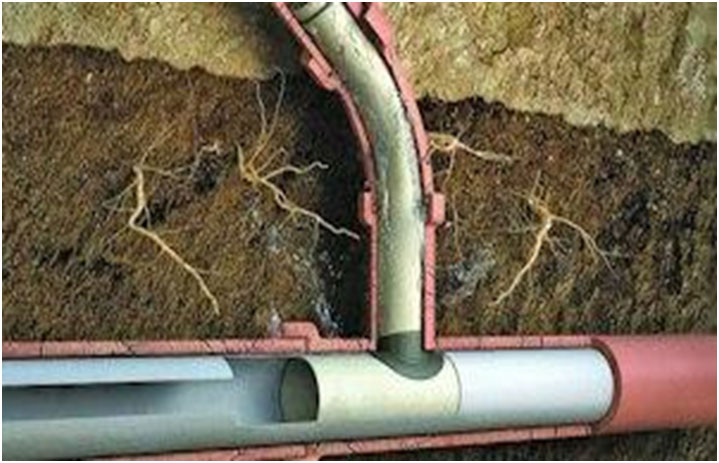

On the other hand, lateral CIPP is tailored for the rehabilitation of smaller diameter pipes that connect individual properties to the main sewer line. These lateral pipes, also known as service or branch lines, play a critical role in transporting wastewater from homes and businesses to the main sewer system. Lateral CIPP employs a similar process to mainline CIPP but is adapted to the specific dimensions and requirements of these smaller pipes.

Image source: LMK Technologies

The main challenge in lateral CIPP lies in the complexity of the network, as lateral pipes often branch off in various directions and connect to different mainlines. Therefore, precise planning and execution are essential to ensure that each lateral is accurately identified and rehabilitated. Despite these challenges, lateral CIPP provides a valuable solution for addressing the specific needs of smaller pipelines without the need for extensive excavation.

Both mainline and lateral CIPP share common benefits, such as reduced disruption, cost-effectiveness, and environmental sustainability. By avoiding extensive excavation, these methods minimize the impact on surrounding infrastructure, traffic, and the environment. Additionally, the seamless liners created through CIPP technology contribute to improved structural integrity, longevity, and resistance to corrosion, extending the lifespan of the rehabilitated pipelines.

Some of the key differences between Mainline CIPP and Laterals:

Main line CIPP typically involves larger-diameter pipes (from 6 to 96 inches) that are mostly circular in shape, while lateral CIPP usually involves smaller-diameter pipes (from 3 to 12 inches) that can be circular, oval, or rectangular in shape.

Main line CIPP uses inversion or pull-in methods to insert the liner into the pipe, while lateral CIPP uses inversion, pull-in, or push-in methods, depending on the length and diameter of the pipe and the type of liner used

Lateral liners are typically designed with flexible fiber reinforcements to provide the ability to stretch and conform to bends, offset joints and irregular piping. Flexible reinforcement of varying fiber type, fiber orientation, density and felt thickness and the type of thermoset resin used influence the entire composite properties.

Main-to-lateral CIPP cured assembly needs to adhere to the requirements of ASTM F1216 and ASTM F2561-20 “Standard Practice for Rehabilitation of a Sewer Service Lateral and Its Connection to the Main Using a One-Piece Main and Lateral Cured-in-Place Liner”.

In conclusion, while mainline and lateral CIPP share a common foundation, their distinct applications cater to the unique challenges posed by different sections of a sewer or pipeline system. Whether rehabilitating the main arteries of a municipal sewer network or the smaller lateral connections, CIPP technology offers a versatile and efficient solution for addressing the aging infrastructure that underlies our communities.

References:

- July 2011, STANDARD SPECIFICATIONS – SECTION 02955 – Sewer mains and lateral rehabilitation by lining, WSSC Water

- Nov 2017, Susen Das et al, Productivity Analysis of Lateral CIPP Rehabilitation Process Using Simphony Simulation Modeling, Journal of Pipeline Systems Engineering and Practice

Volume 9, Issue 1https://doi.org/10.1061/(ASCE)PS.1949-1204.0000297

- (2011). “Standard practice for rehabilitation of a sewer service lateral and its connection to the main using a one piece main and lateral cured-in-place liner.” ASTM F2561-11, West Conshohocken, PA.

- Mainline Connections & Laterals | Waterline Renewal Technologies