Airtight CIPP tube is fabricated by stitching the adjoining edges of the coated felt and sealing the seam area with a thermoplastic sealing strip.Tubes are usually sewn together with an edge-to-edge (butt) sewn seam to create an even seam surface and thickness. Sealing options include direct extrusion of a compatible polymer or welding of thermoplastic seam tape by hot air/gas or solvent. Careful consideration of the different processing factors involved in these sealing methods are necessary for consistent seam quality and throughput.

This chapter provide further insights on the influence of the thermoplastic polymer properties and critical quality aspects of seam tape/sealing strip for hot air and solvent welding techniques. Using compatible thermoplastic polyurethane (TPU) and polyolefin (TPO) polymer extrusion or seam tapes for TPU- and TPO-coated felt is recommended to ensure superior adhesion to the coating of the main/lateral liners as well as maintaining the required mechanical strength, thermal and chemical resistance characteristics of the CIPP tubes.

Extrusion technique

Extrusion is an advanced and effective technique in sealing the sewn seams to form the final tubes. Determination of the melt flow index of the TPU or TPO pellets is necessary to ensure optimal processing of the TPU or TPO, which includes barrel temperatures, screw speed and pressure control to produce a homogenous, Higher melt flow TPU or TPO usually requires less heat to process. A controlled extrusion process is critical for consistent gauge and melt viscosity for strong adhesion (film tearing bond) to the TPU or TPO-coated layer on the sewn seam.

Hot-air welding technique

Hot air welding has proven effective and durable in the sealing of CIPP tubes using compatible seam tapes. This technique involves thermally welding the interface of the TPU/TPO seam tape and coating on sewn seam of the tube with a heated air flow. Hot air welds are permanent, airtight and come to full weld strength almost immediately. Determination of hot air temperature (typically +485oF), pressure and speed controls according to the film thickness and TPU/TPO thermal properties is important to ensure that the crystalline thermoplastic layers softens and melts to form a permanent weld when the thermoplastic cools. If excessive heat is applied, thermal degradation may occur where the thermoplastic sealing strip can shrink or burn while insufficient heat results in a defective weld due to poor fusion on the thermoplastic layers.

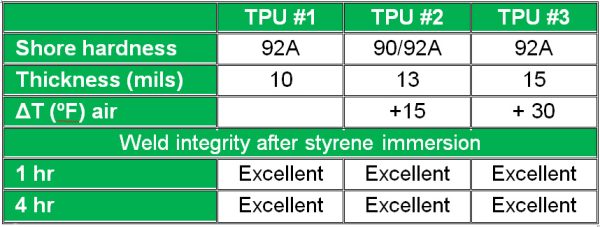

The weld characteristics of the thermoplastic TPU depends on the amount of crystallinity, where softer TPU tapes typically require less heat to thermally fuse. Table below indicates increase of temperature by 30 oF with increase of TPU shore hardness.

Data obtained using a MillerweldmasterT300 Flex hot air welding machine. Speed 10 FPM, 8 psi, 485 – 550 oF.

Solvent welding technique

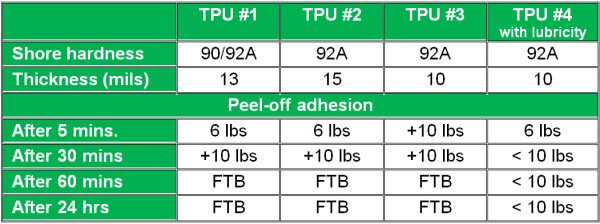

Solvent welding is a process where solventwith no dissolved polymer is applied to soften and dissolve the surface of the interfacing thermoplastic layers.This process forms a cohesive connection through molecular diffusion between the contacting layers. Tetrahydrofuran (THF) is used for solvent welding TPU due to its high solubility strength in creating a high-strength weld after a short time. The table below shows that TPU with higher shore A hardness tends to be more resistant and requires a longer reaction time than softer TPU’s. We also found that the presence of additives in TPU matrix can influence the strength of the solvent weld.

FTB – film tearing bond

The following criteria are important for high-quality solvent welding:

- Compatible TPU matrix and shore hardness for effective solvation and allowing THF to permeate out to form a strong weld bond.

- Suitable thickness of the seam tape – typically comparable to the liner coating.

- Excellent lay flat quality and gauge consistency of the seam tape to avoid air pockets.

- Skills and knowledge on the operator part is integral to obtain a consistent high-quality weld.

In practice, compatible thermoplastic TPU or TPO polymers is recommended for sealing the sewn seams in the final CIPP tube fabrication and careful determination of sealing process conditions according to the physicochemical properties of the seam tapes is required for superior weld strength and performance.